How an Optical Fibre Diameter Analyser Contributes to the Development of Future Fibre Optic Systems

Just How an Optical Fibre Diameter Analyser Boosts Quality Assurance in Fibre Production

The combination of an Optical Fibre Diameter Analyser into Fibre production processes stands for a substantial advancement in quality assurance methods. By providing real-time, precise dimensions of Fibre sizes, this innovation deals with the critical demand for consistency in production requirements. With its ability to promptly identify inconsistencies and timely corrective procedures, the analyser not only improves product dependability but additionally contributes to general operational effectiveness. As industries progressively focus on high quality and conformity, understanding the complete influence of such advancements comes to be vital. What implications could this have for the future of Fibre manufacturing?

Relevance of Fibre Diameter Dimension

Exact dimension of Fibre Diameter is crucial in the field of optical Fibre technology, as it directly influences the performance and reliability of Fibre optic systems. The Diameter of an optical Fibre influences its light-carrying ability, depletion, and total transmission performance. Accuracy in gauging Fibre Diameter guarantees that the optical residential properties are kept within defined resistances, which is important for ideal signal integrity.

Variations in Fibre Diameter can cause boosted losses because of scattering and modal dispersion, impacting the top quality of information transmission. In high-speed interaction systems, such inconsistencies can result in significant destruction of signal top quality, causing data errors and lowered efficiency. Additionally, consistent Fibre Diameter is vital for compatibility with connectors and splicing modern technologies, which are indispensable parts of Fibre optic networks.

Quality assurance processes in Fibre production heavily rely upon accurate Diameter measurements to ensure conformity with sector requirements. By implementing durable measurement strategies, makers can enhance item reliability, decrease waste, and improve total system performance. Therefore, the significance of Fibre Diameter dimension can not be overstated, as it functions as a cornerstone in the improvement of optical Fibre technology and its applications in contemporary communication networks.

Exactly How the Analyser Functions

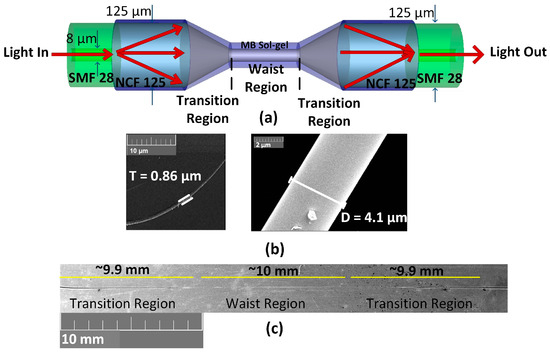

The efficient dimension of Fibre Diameter relies upon advanced logical techniques that make sure accuracy and dependability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser uses a combination of laser innovation and progressed image processing formulas to accurately evaluate the Diameter of fibers as they are produced

At first, a laser light beam is directed at the moving Fibre, developing a cross-sectional shadow. The analyser catches this darkness making use of high-resolution video cameras positioned purposefully along the manufacturing line. The captured pictures are after that refined in real-time to determine the Fibre's Diameter with outstanding precision.

The system utilizes sophisticated algorithms that represent numerous variables, including variations in light intensity and environmental conditions, to improve dimension integrity. It can detect minute changes in Diameter, such as fluctuations that might happen during the manufacturing process.

Additionally, the analyser can taking care of numerous fibers concurrently, boosting throughput without jeopardizing accuracy. By offering instant feedback on the Diameter, the Optical Fibre Diameter Analyser plays an important role in maintaining rigorous quality assurance criteria, making sure that the end product fulfills market specs and customer requirements.

Advantages of Real-Time Tracking

While conventional methods of checking Fibre Diameter often entail lengthy post-production checks, real-time monitoring significantly boosts the effectiveness and quality of optical Fibre manufacturing. optical fibre diameter analyser. This aggressive technique allows suppliers to determine deviations in Fibre Diameter as they take place, rather than waiting till production is full to examine quality

By continually measuring the Diameter during manufacturing, manufacturers can make certain that the fibres fulfill strict requirements, resulting in lowered variability and boosted consistency. Real-time surveillance also allows immediate restorative activities to be taken, reducing waste and protecting against defective fibers from getting in the supply chain.

Additionally, this modern technology helps with improved information collection and analysis, supplying understandings into production fads and possible areas for enhancement. Such data-driven decision-making encourages manufacturers to enhance procedures and keep high standards of top quality control.

Furthermore, real-time tracking promotes a society of continuous enhancement within the manufacturing environment. Workers are extra involved when they can see the effect of their operate in real-time, resulting in increased liability and a dedication to quality. Overall, the application of real-time tracking systems in optical Fibre production converts to premium item quality and increased customer fulfillment.

Influence On Manufacturing Performance

Applying optical Fibre Diameter analysers dramatically boosts manufacturing performance by streamlining the production procedure. These tools promote continual surveillance of Fibre Diameter, allowing producers to spot discrepancies in real-time. By determining disparities quickly, assembly line can be adjusted promptly, reducing downtime and reducing click to investigate the likelihood of generating malfunctioning products.

Additionally, the integration of these analysers right into the manufacturing process enables far better source allotment. With accurate Diameter measurements, operators can maximize material usage, making certain that sources are not squandered on flawed fibers. This precision additionally adds to less scrap and revamp, eventually lowering manufacturing costs.

The automation given by optical Fibre Diameter analysers minimizes reliance on hand-operated evaluations, which are vulnerable and typically time-consuming to human mistake. As a result, staff members can focus on even more strategic jobs, enhancing general productivity.

Additionally, the data produced from these analysers can educate process renovations and help with far better decision-making. By evaluating patterns in Fibre Diameter variants, manufacturers can carry out aggressive steps to improve manufacturing techniques and preserve regular high quality. In recap, optical Fibre Diameter analysers play a vital duty in boosting production performance, leading to higher high quality result and increased earnings.

Study and Success Stories

Across different fields, study highlight the transformative effect of optical Fibre Diameter analysers on manufacturing procedures. One prominent example is a leading telecommunications business that encountered obstacles with irregular Fibre diameters, leading to enhanced being rejected prices. By incorporating an optical Fibre Diameter analyser, the firm attained real-time monitoring of Fibre dimensions, resulting in a 30% reduction in defects and significant cost savings.

Moreover, a research establishment concentrating on advanced products used optical Fibre Diameter analysers to improve their speculative processes. The analyser's ability to offer Click Here thorough insights right into Fibre uniformity allowed the development of ingenious materials with enhanced performance attributes.

These success stories highlight the important duty of optical Fibre Diameter analysers in boosting high quality control, boosting production performance, and driving development throughout diverse markets.

Verdict

In final thought, the Optical Fibre Diameter Analyser plays an essential duty in boosting top quality control within Fibre manufacturing. As shown via numerous instance researches, the analyser confirms essential for achieving superior product quality in Fibre production.

The execution of optical Fibre Diameter analysers enabled for stringent top quality control, making sure that the produced fibers met exacting sector standards.In verdict, the Optical Fibre Diameter Analyser plays a critical duty in enhancing top quality control within Fibre manufacturing.